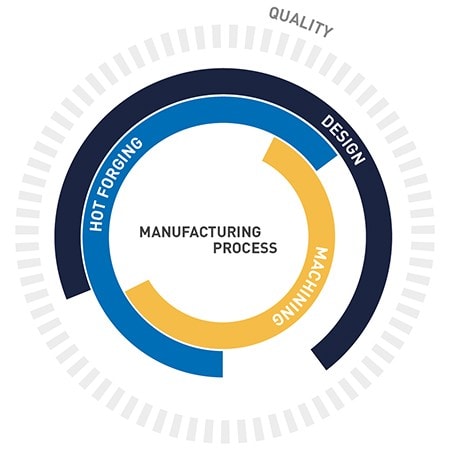

THE MANUFACTURING PROCESS

We constantly invest in research and technological development to improve our products and production methods, bringing all our expertise to bear to offer the customer the optimal solution.

Highly skilled staff and the use of state-of-the-art measuring instruments enable us to ensure total control in every phase of the manufacturing process.

We have a Research and Development department that works directly with the customer to fully understand the required product and deliver exactly what is needed (co-engineering).

We have a Research and Development department that works directly with the customer to fully understand the required product and deliver exactly what is needed (co-engineering).

The production chain starts with the design and construction of dies and the in-house production of tools and equipment for the manufacture of products, which vary greatly in size and shape. These activities have enabled Gnutti Cirillo S.p.A. to become world leader in the production of brass O.E.M. (Original Equipment Manufacturer) products.

The company’s equipment, constantly updated and maintained at the state of the art, comprises a large number of presses of various sizes (up to 2,700 t), able to produce items from 11 g to 40 kg.

High productivity thanks to automation, constant quality, mechanical strength, precision and material uniformity are just some of the benefits offered by the hot forging system, which forms pieces directly from the bar stock.

Our machines’ total reliability and precision enable us to perform machining operations with very tight tolerances, guaranteeing a precise, reliable finished product.

Our products’ precision and reliability are achieved through Total Quality, which starts in the design phase and extends throughout the entire manufacturing process.

Meticulous procedures, instructions and inspection plans using modern 3D machinery and SPC (Statistical Process Control) software complete a product of genuine excellence.

THE PHASES

Design We design and produce the equipment and tools necessary for the production of the most complex articles in-house.

Production of dies and tools With the aid of cutting-edge CAD-CAM systems, our project managers collaborate with customers to examine and analyse their needs and offer the ideal solution.

Raw material All our suppliers are required to comply with the highest raw material quality standards. Strict inspections guarantee the excellent quality of the used raw material.

Hot forging Our machinery, thanks to its state-of-the-art technology, makes us the world leader in hot forging.

Machining The precision and capacity of our CNC machines optimise the finished product, guaranteeing compliance with strict tolerance levels and minimal roughness values. An automatic cleaning and drying system installed on the machine ensures a perfect product before packaging.

Assembly Assembly (manual or automatic), by highly skilled staff, is available as a service to customers.

Logistics We offer JIT, Kanban and other types tailored to the customer's needs.

Storage and warehouse We guarantee the maintenance of equipment for continuous business.

Quality assurance Quality assurance guaranteed by the ISO 9001 standard

Quality control Strict control plans constantly enforced by highly skilled staff who receives continual training.